In our new case, we would like to discuss the second phase of an ongoing project for a manufacturing company.

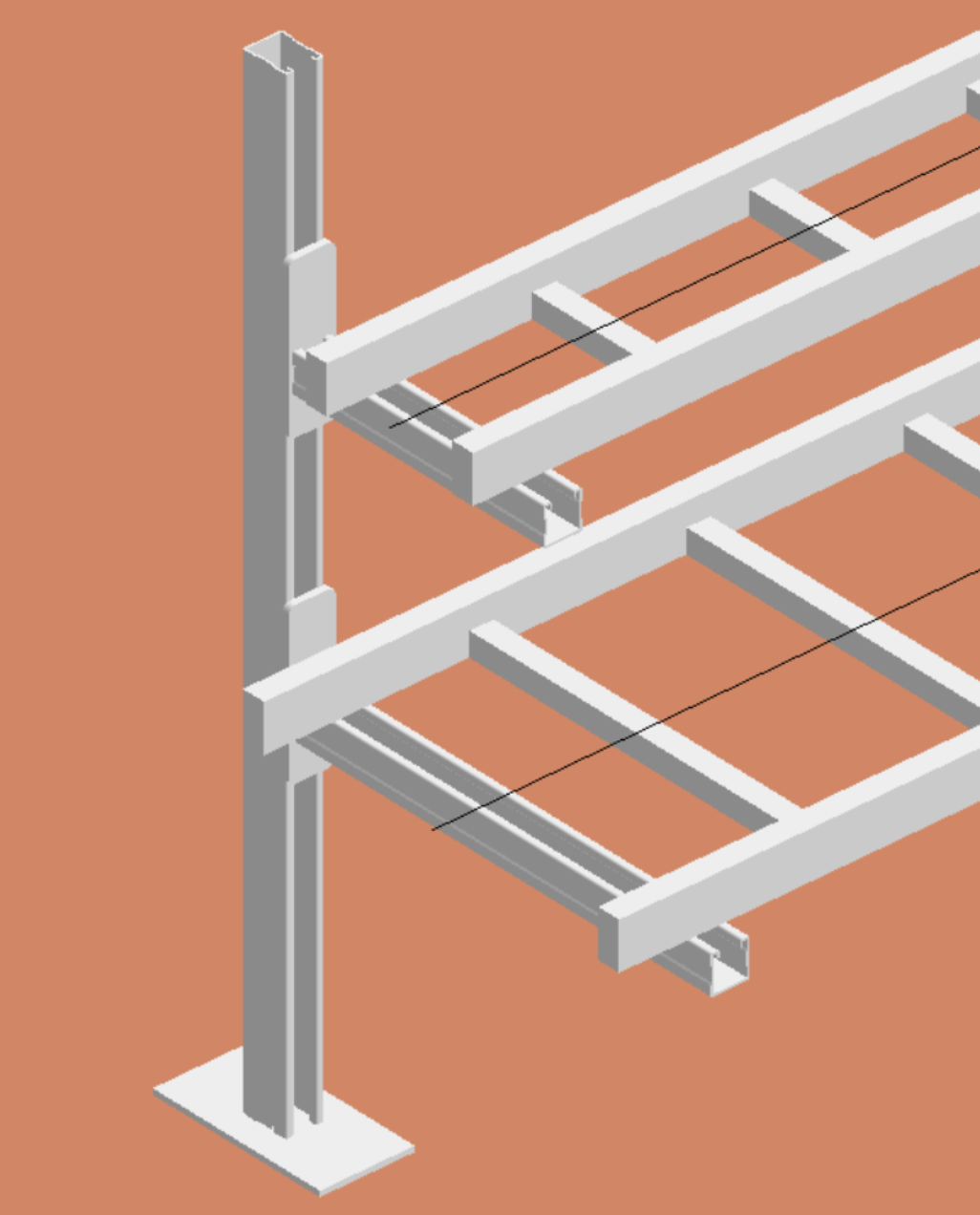

As part of the project, a plugin was developed for designing cable tray routes using the company's manufactured products.

The plugin’s purpose is to simplify the work of design engineers by providing functions for automatic calculation and placement of fixings, segmentation, selection of tray sizes, and access to a catalogue of real-world products.

Our team has developed a multifunctional solution.

The plugin’s purpose is to simplify the work of design engineers by providing functions for automatic calculation and placement of fixings, segmentation, selection of tray sizes, and access to a catalogue of real-world products.

Our team has developed a multifunctional solution.

Load Verification Functionality

The development of the plugin provided us with extensive experience in the automatic generation of elements in Revit. The first version of the plugin includes functionalities for configuring and creating tray routes, segmentation, support spacing calculation and placement along the route, load verification, and automatic generation of Revit specifications with all route elements, including fasteners.

For its operation, the plugin uses a dedicated set of parameters that are loaded upon first launch.

For its operation, the plugin uses a dedicated set of parameters that are loaded upon first launch.

Support Selection and Placement Interface

We chose an approach based on geometric boundaries. Every model element with geometry has defined boundaries—two spatial points that enclose the entire element. We check whether the boundaries of a support intersect with those of a tray. For each support that passes this check, we further determine which specific bracket intersects with the tray. This allows us to gather information about the actual positioning of elements in the model, eliminating errors caused by user actions.

Following this, we calculate the support spacing and perform load calculations for the route, highlighting failed supports and spans in the view.

The development of this plugin has provided us with extensive expertise in automating the creation of elements in Revit. We now have a ready-made system for constructing linear elements (trays/pipes/ducts) and placing components along them, with the ability to conduct calculations and assign specific catalogue sizes. This system can be adapted for similar tasks or developed into a new solution to meet specific requirements.

Following this, we calculate the support spacing and perform load calculations for the route, highlighting failed supports and spans in the view.

The development of this plugin has provided us with extensive expertise in automating the creation of elements in Revit. We now have a ready-made system for constructing linear elements (trays/pipes/ducts) and placing components along them, with the ability to conduct calculations and assign specific catalogue sizes. This system can be adapted for similar tasks or developed into a new solution to meet specific requirements.

For Revit solutions, feel free to contact VirTex!